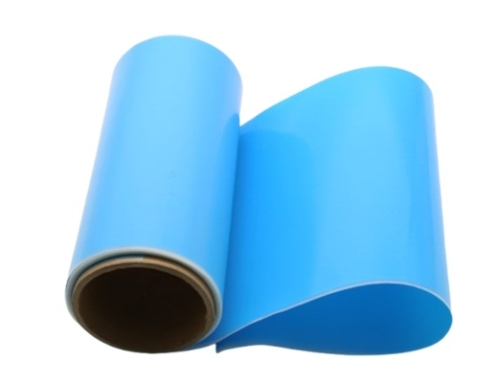

Teflon coating fabric, long lasting release sheet for plastic and polymer processing

Teflon coating fabric with or without adhesive, is used as release sheet or conveyor belt in plastic and polymer processing applications. From the producing and curing of foam (like polyurethane foam), PVC window & door welding, plastic bag manufacturing, to rubber & composite polymer curing and cooling.

ESONE Teflon coated fabric will be the best solution for consistent long lasting performance, minimize equipment off-time, ensuring the product quality.

How to use Teflon coating fabric for Plastic and Polymer processing

High temperature and high pressure will be requested in curing or laminating process, and easy release, heat resistant to 260 degrees surface of PTFE, combined with the high mechanical strength of fiberglass, which allows Teflon coated cloth used as release sheet or releasing conveyor belt, for a wide range of plastic and polymer processing industries.

Upper and Lower Teflon Sheet will cover the composite plastic or polymer during heat pressing lamination, resulting in excellent smooth surface of the product, and minimize the off-time of the production line.

Non stick PTFE conveyor belt is used for delivering uncured rubber or polymer, through the static pressing machines, high temperature ovens, then to the cooling parts finally.

Applications of Teflon coating cloth for Plastic and Polymer processing

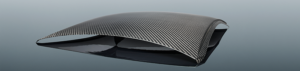

1) Automotive composite manufacturing

With high temperature and abrasion resistance, Teflon coating fabric is working as release sheet in the production of automotive composite, which is light weight and high strength. Such as RMT, GMT, SMC(sheet molding compound).

Auto seat, front ends, door carrier, parcel shelf, arm resting parts will use PTFE coated fabric with or without adhesive for excellent release.

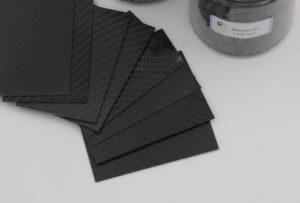

2) Carbon fiber reinforced composite

Carbon fiber is a new kind of high modulus, high strength fiber, with carbon content of more than 95%. Carbon fiber reinforced composite has higher strength than steel, and is much more lighter and softer. It’s widely used in national defense, military industry and civil use industry, such as aircraft industry, automotive industry and so on.

During the lamination of Carbon fiber reinforced composite, Teflon coating fabric will be used as conveyor belt and release sheet in the processing of heat press. Or be cut into the shape of product (like Carbon fiber hockey), and act like release fabric for the product.

High tensile Teflon coated fabric will be needed for this industry.

3) Foam production and curing

Teflon fabric can resist the high curing temperature of different foam, especially polyurethane foam, which has the highest curing temperature. High tensile and long lifetime of the PTFE coated fabric will be critical to the quality of product and the production output.

4) Polymer composites curing & casting and Plastic molding

Teflon coating fabric with or without adhesive work as mold release sheet for polymer composites curing & casting and plastic molding, since Teflon fabric is abrasion resistant, heat resistant to 500F, easy release.

5) Plastic bag manufacturing

Plastic bag is heat welded to seal the edges, and the production line is sealing and cutting in a high speed. According to customer’s request, PTFE coated fabric or Self adhesive PTFE coated tape will be used for this application, in order for resisting high temperature, and release the plastic bag easily from the welding part.

6) PVC window & door welding release

Continuous working in high temperature, consistent release property is request when welding PVC windows and doors. Teflon coating fabric has excellent release surface and can resist heat up to 260°C, which can prevent melted PVC from sticking on welding platens.

Teflon coated fabric is workable for all kinds of welding process, including RF and microwave systems.

Teflon fabric is a non stick release sheet or release belt for polymer or plastic curing or laminating.

As the composite material is developing fastly, the quality request for PTFE fabric will be higher, in order for meet the demand of machines with higher speed

My application is holding a sheet of carbon fiber down to a vacuum jig which has an array of small holes for the vacuum. the surface of the carbon fiber is too rough so the vacuum can’t hold it.

I hope that a layer of your PTFE fabric can help the vacuum to adhere

Hi Dr. Joleen Pater, YS9006P is a porous release sheet, and we think it might work for your application. It is worth trying anyway.

Our sales team will contact with you soon:)

Pleas advise how the teflon is applied to the sheeting. I have a particular project in mind that requires very high tensile strength fabric, with antifouling properties for the marine use. The idea of applying teflon is to act as antifouling, while at the same time as a vu resistance as product needs long life in outdoor environment. difficulty is will need to use Ultra high density polyethylene to create a sufficiently strong fabric and that this is not temperature stable… Also, should we find appropriate solution would need to produce lengths of 1000 m of treated fabric. How diverse is your company can you manage new product development. Please send all available details.