PVDF Film

ESONE’s PVDF films are melt extruded casting film manufactured from Polyvinylidene Fluroride resins. PVDF foils has all the properties of fluoropolymer films and it has strong processibility, meanwhile, PVDF membrane can be heat sealed and laminated to many kinds of substrates like PVC, Floor, Color steel tile and Aluminium-plastic panel.

Due to the following properties, PVDF film is widely used in Wallcovering, Solar back protection, Thin-film Cell, outdoor metal film-coated plate and many other applications.

- Superior chemical & environmental & weather resistance

- Non stick property

- Excellent dielectric strength

- Fire resistance (UL V-0 rating – international standard, A0-class – China)

- Low friction property

- Strong UV resistance

- Continuously working up to 300°F (150°C)

ESONE offering PVDF films in a various thickness from 0.001” to 0.03” (25 to 760 μm), the maximum width can be 90” (2,280mm). Any kinds of surface can be offered for easy lamination, including chemical etching, corona treatment. And the standard color including white, transparent and other customized color.

PVDF Film Applications

Wallcovering

Monochromatic or Transparent PVDF films can be laminated with PVC, PET or other substrates, resulting in a non stick & bacteriostatic & ageing-resistant wallcoverings.

The excellent properties including

- Non stick – Easily remove any stains

- Fire resistance – UL V-0 rating – international standard, A0-class – China

- Environmental resistance – Permanently new!

- Bacteriostatic – Not only bacteriostatic, but also not afraid of disinfectant fluid

Now ESONE PVDF wallcovering has been widely used in hospital, since this film is bacteriostatic, easy to clean and can resist to disinfectant fluid. It is normally used in inpatient ward, aisle, hall and other crowded places.

The PVC or PET substrates can be customized into any design that you like! Contact us for offering various choices!

Office wallcovering

Home wallcovering

Children room wallcovering

Hospital wallcovering

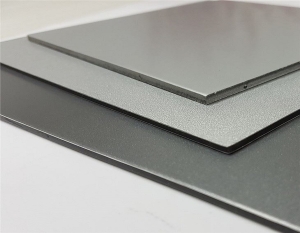

Steel & PVC & Wood

Due to the weathering and abrasive resistance, ESONE PVDF films is typically used as the environmental ageing protection for colored steel, alumium sheet or floor.

The special formulated PVDF film has one special side which can laminate these substrates. The lamination process can be heat lamination or chemical lamination.

Floor laminating

Color steel tile laminating

PVC membrane laminating

Aluminium plastic panel laminating

Aircraft & High speed train Decoration

ESONE PVDF film for Aircraft & High speed train Decoration is using pure PVDF film to laminate the wall, resulting in a non stick and easy to clean activity space.

Along with the growing needs for disinfection, more and more companies are using PVDF film to cover the wall, floor and ceiling, so that all the space is film covered, clean and safe.

Solar back protection

ESONE PVDF film for solar back protection is specially formulated for offering 100% UV blocking, excellent vapour blocking and anti-aging property. This film is white color and is one side or both sides corona treated.

Our PVDF film has high adhesive strength to polyurethane glue and EVA adhesive sheet, and it can offer more than 25 years anti-aging services. Moreover, it is widely used as the surface protective film for metal sheet, outdoor advertising box and others.

PVDF Film Technicial Data Sheet

Sizes:

ESONE offering PVDF films in a various thickness from 0.001” to 0.03” (25 to 760 μm), the maximum width can be 90” (2,280mm).

PVDF Film surface:

Any kinds of surface can be offered for easy lamination, including chemical etching, corona treatment.

The standard color including white, transparent and other customized color.

Applicative substrates:

- Plastics: PVC, PET, PP, PETG, PMMA and others

- Wood: Floor, Particle board and others

- Stone: Marble, Tile, Granite, rock beam and others

- Metal: Aluminum plastic board, Aluminum veneer, Color steel plate and others

- Composite material: FRR board, GRC board, Medium density board and others