PTFE Glass Coated Fabric for Copper Clad Laminate(CCL)

PTFE Glass Coated Fabric is using E-glass fiber (or Kevlar, Nomex) as basic fabric, and impregnated with high quality PTFE (Teflon)(Polytetrafluoroethylene).

PTFE prepreg fabric is used in CCL production, in order for meeting the high frequency request in 5G.

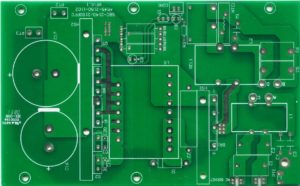

What is Copper Clad Laminate (CCL)?

Copper Clad Laminate(CCL) is a type of basic material of PCB, it is laminated with copper clad on both sides, and reinforced with resin soaked glass fiber fabric.

Classification of CCL

Due to the different classification standard, CCL can be classified into many kinds of categories:

★ Mechanical rigidity

Rigid CCL or Flex CCL. It depends on the rigidity, while flex CCL is used to make Flexible Printed Circuit board/FPC.

★ Insulation material and structure

Organic resin CCL, Ceramic-base CCL, Metal-base CCL

★ Thickness

Standard thickness CCL and thin CCL. The standard one is at least 0.5mm thick.

Thickness of copper foil is included in the CCL thickness.

★ Reinforcing material

Glass fiber based CCL, paper based CCL, compound CCL

★ Applied insulation resin

Epoxy resin CCL and Phenolic CCL.

Prepreg(reinforcing material) for CCL

Prepreg is the reinforcing material for CCL, is made with fiberglass coated with resin.

The common glass fiber fabric for CCL is 106, 1080, 2112, 2116, 1500 and 7628.

And the applied resin is Phenolic resin, epoxy resin, Polyimide resin, Bismaleimide triazine or PTFE Glass Coated Fabric.

Due to the following property of glass fiber cloth, so it is widely used as prepreg material in CCL.

★ High intensity

★ Heat and fire resistance

★ Humidity resistance

★ Excellent insulation capability

The quality of prepreg will affect the quality of CCL directly.

Therefore, ESONE pay high attention to the testing and controlling of prepreg quality, which includes the resin content, gel time, volatile content and resin fluidity.

Why use PTFE Glass Coated Fabric for HFPCB production

With the development of 5G communication technology, high frequency printed circuit board is requested.

Because of the following superior property of PTFE Glass Coated Fabric, it is used as reinforcing material in CCL production, which can meet the high request of High frequency printed circuit board(HFPCB).

Unique request for PTFE coated fabric, PTFE film in CCL production

ESONE is developing custom PTFE Glass Coated Fabric for CCL production, like improving the welding property, promoting the dielectric strength and enhancing the tensile strength (dimensional stability).

And the workshop must be clean, temperature and humidity must be constant, otherwise the electricity property may be affected.

And in order to reduce the fragment during drilling holes, high quality PTFE film will be needed inside the sandwich of CCL.

How many layers of PTFE fabric will be requested for copper clad laminate?

Hi John, thanks for your comment! Normally it can be 3-15 layers of PTFE fabric will be requested for lamination.