PTFE coated fiberglass is used in many processes of Textile manufacturing

PTFE coated fiberglass is used in the digital printing and drying, garment fusing, lamination of textile, process of woven or non woven fabric, applications of casting or curing, flooring mat manufacturing and so on.

The selection of PTFE fabric is according to the application of customer’s equipment, ESONE fabric or belt can provide long lasting performance and maximize the up-time of production line, improve the capacity and quality of the product.

Digital Printing and Drying

Digital printing is a modern way to print pattern, different from traditional printing, digital printing minimize the printing cost and speed up the printing time.

PTFE mesh conveyor belt is used in the digital printing and drying, since PTFE mesh belt is Non stick, heat resistant, easy to install and cost-effective.

Garment Fusing and Textile Lamination

PTFE coated fiberglass is used as conveyor belt for Garment Fusing and Textile lamination machines, like Hashima, Oshima, Veit, Meyer, Macpi fusing machines and so on.

Since PTFE belt is anti-stick, heat resistant and can run continuous, so it is the must use belt in fusing application.

The belts for fuse & press & lamination machine is as follows.

Using fiberglass or Kevlar as basic material, weaving into a endless belt, and coated with high quality PTFE.

Since this belt has no joint, so the lifetime is at least 3 times longer than PTFE belt with joint, and will run in straight continuously.

This belt is black/brown/white, and can be Anti-static.

★ PTFE Belt with joint

Coating with imported PTFE(Teflon), and joint the PTFE fabric into PTFE conveyor belt.

This belt is a cost-effective choice for fusing machine belt.

This belt is black/brown, and can be Anti-static.

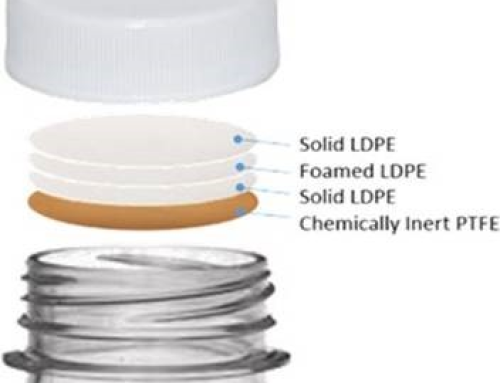

With 2 layers laminated, this PTFE belt has much higher tensile strength than normal belts.

The inside layer is Anti-static PTFE fabric, and the outside layer is PTFE coated fabric with high tear strength.

This belt is black/brown, and can be Anti-static.

Thermal bonding of Non-woven fabric

The heat resistant and non stick PTFE coated belt, is the critical feature of the thermal bonding process of non woven manufacturing.

During the drying process, the cotton with or without glue, the fiber with low melting point need to be dried and cured, then a PTFE mesh belt or PTFE heavy duty belt will be needed.

Specification of PTFE Belt for Textile manufacturing

| PTFE mesh fabric for Textile manufacturing | |||||

|---|---|---|---|---|---|

| Style | Mesh Size (mm) | Weft | Color | Weight (g/m2) | Tensile Strength Warp/Fill (N/cm) |

| YS6001 | 1x1 | Single weft | Brown/White | 440 | 430/285 |

| YS6003 | 4x4 | Single weft | Black | 540 | 300/440 |

| YS6004 | 4x4 | Single weft | Brown | 540 | 300/440 |

| YS6007 | 4x4 | Fill-Fiberglass Warp-Kevlar | Brown | 560 | 690/460 |

| YS6008 | 4x4 | Double weft | Brown | 575 | 370/690 |

| YS6008S | 4x4 | Double weft Stronger fiberglass yarn | Brown | 720 | 540/700 |

| YS6008HS | 4x4 | Double weft Much stronger fiberglass yarn | Brown | 1200 | 700/750 |

| YS6012 | 4x4 | Double weft | Black | 600 | 300/690 |

| YS6013 | 10x10 | / | Brown | / | / |

| YS6014 | 2x2.5 | / | Black | / | 375/280 |

| YS6015 | 2x2.5 | / | Brown | / | 375/280 |

| YS6016 | 2x4 | / | Brown | / | / |

| YS6016S | 2x4 | Stronger fiberglass yarn | Brown | / | / |

| YS6018 | 8x8 | / | Brown | / | / |

| PTFE Heavy Belt for Textile Manufacturing | |||||

|---|---|---|---|---|---|

| Style | Standard Width(mm) Please ask for other widths | Normal Thickness (mm) | Weight (g/m2) | PTFE Content (%) | Tensile Strength Warp/Fill (N/cm) |

| YS9035AJ | 1000, 1500, 2600 | 0.35 | 680 | 64 | 540/508 |

| YS9045AJ | 1000, 1500, 2600 | 0.45 | 900 | 55 | 540/508 |

| YS9060AJ-ESONE | 2500, 2760 | 0.60 | 1170 | 50 | 880/840 |

| YS9063A | 2350 | 0.63 | 1140 | 48 | 880/840 |

| YS9066A | 2260 | 0.66 | 1050 | 45 | 890/850 |

| YS9068A | 2450 | 0.68 | 1015 | 41 | 890/850 |

| YS9070A | 2550 | 0.70 | 1100 | 46 | 860/820 |

| YS9075A | 1500 | 0.75 | 750 | 40 | 780/760 |

| YS9076A-1 | 2350, 2550 | 0.76 | 1015 | 43 | 800/780 |

| YS9076A-2 | 3800 | 0.76 | 1150 | 50 | 840/800 |

| YS9079A | 3800 | 0.79 | 1290 | 55 | 840/800 |

| YS9088A | 1230 | 0.88 | 1230 | 42 | 1200/1100 |

| YS9089A | 3800 | 0.89 | 1085 | 38 | 1120/1020 |

| YS9090P | 1500 | 0.90 | 1150 | 25 | 1200/1100 |

| YS9090A | 2800 | 0.90 | 1610 | 52 | 1300/1200 |

| YS9094A | 1600 | 0.94 | 1050 | 20 | 1200/1100 |

| YS9095A | 1500, 2600 | 0.95 | 1385 | 36 | 1200/1100 |

Leave A Comment