PTFE Casting Film

PTFE Casting Film/PTFE Cast Film

ESONE’s PTFE Casting Film is crafted entirely from pure PTFE (Polytetrafluoroethylene) using a cast manufacturing method. This film can be produced as either a multi-layered or single-layer film, making it versatile for a wide range of applications. It is specifically engineered to withstand exposure to chemicals, heat, and mechanical stress, where low friction properties are essential. This makes it particularly suitable for environments where gases or corrosive liquids may be present, especially at elevated temperatures.

| The differences between various PTFE films | |||

|---|---|---|---|

| Material | PTFE casting film | PTFE skived film | PTFE extruded film |

| Flexibility | Soft | Hard | Medium |

| Pin hole | No Microholes | Many Microholes | Few Microholes |

| Chemical Resistance | High | Low | Medium |

| Friction | Low friction | Medium friction | High friction |

| Elongation | High | Low | Medium |

| Min thickness | 0.00025'' 0.005mm 5um | 0.0005'' 0.012mm 12um | 0.002'' 0.055mm 55um |

| Coating | Can coat PFA or FEP | No coating | No coating |

| Strength | amorphous | Medium | unidirection |

Advantages

This film is characterized as a relaxed amorphous material, allowing it to be uniformly stretched in all directions without exhibiting stress whitening, which makes it an effective barrier against gases and liquids. It boasts a high purity level, is non-porous, and free from pinholes. Our Cast Films provide excellent drapability and conformability, along with outstanding dielectric properties. ESONE offers these films in both clear (unpigmented) and colored options, including red, blue, white, yellow, and tan. Additionally, surfaces suitable for cementing and bonding are available.

Specification of PTFE Casting Film

Our PTFE Casting Film is available in a range of thicknesses from 0.005 to 0.127mm (0.25 to 5mil) (5um to 127um) and can be produced in widths up to 60 inches (1524 mm). This variety in thickness and width allows for tailored solutions to meet specific application requirements.

Filler: 1. No filler. 2. Silica. 3. Others

Coating:1. No coating. 2. PFA coating. 3. FEP coating

Color: Half Transparent, Red, Blue, Black, Green, Copper and others

Applications of Cast PTFE Film

ESONE’s PTFE Casting Film is ideal for use in various industries where chemical resistance, low friction, and thermal stability are critical. Common applications include:

- Chemical Processing: Used in equipment and containers that handle aggressive chemicals.

- Food Processing: The high purity and non-porous nature make it safe for food contact applications.

- Electrical Insulation: Due to its excellent dielectric properties, it is suitable for insulating electrical components.

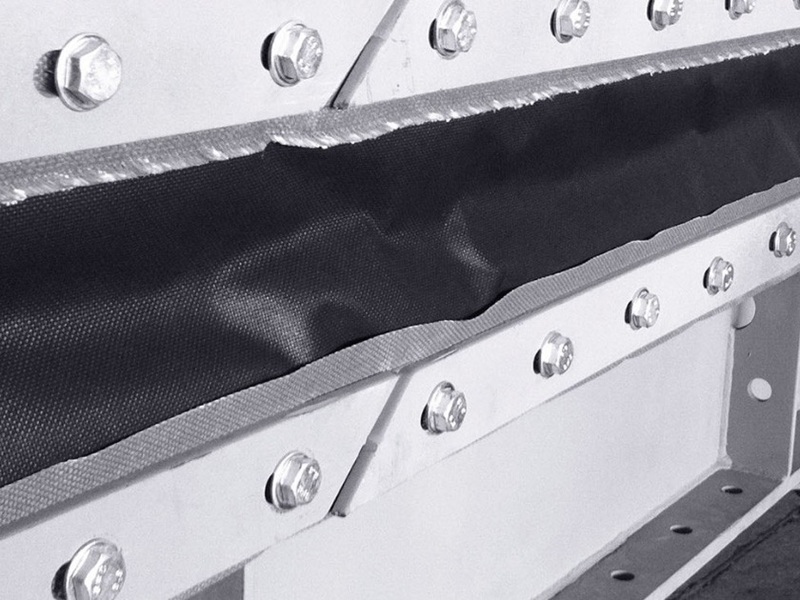

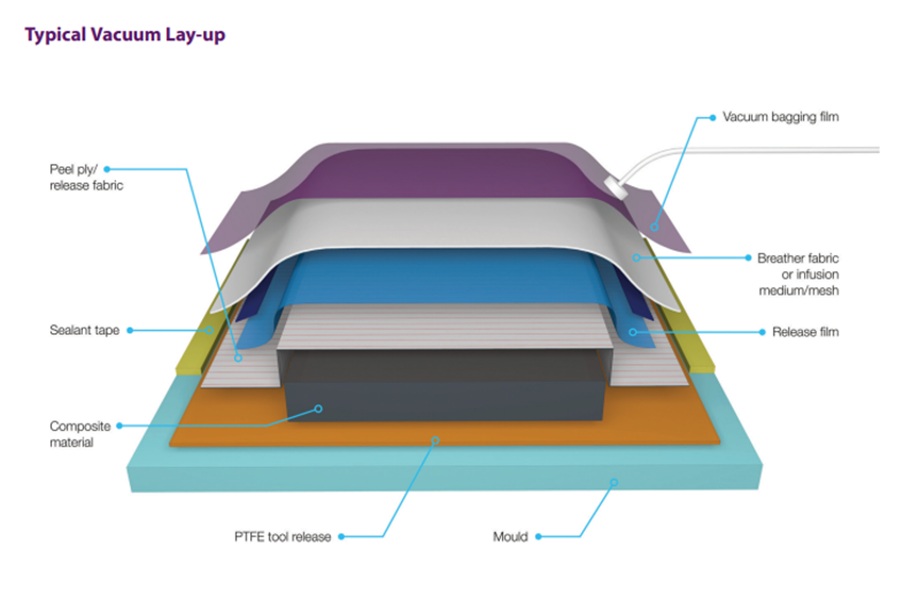

- Vacuum Bagging mold release: suitable for the upper end temperatures required in the fabrication of high performance composites for the aerospace industry.

- Outdoor Applications: Its durability and resistance to environmental factors make it suitable for outdoor use where exposure to the elements is a concern.

| Property | PTFE Cast Film |

|---|---|

| Color | Red, Blue, Black, Half Transparent |

| Standard width mm(in) | 450(17.7), 500(19.7), 955(37.6), 1,000(39.4), 1,250(49.2), 1,524(60) |

| Thickness Available mm(mil) | 0.005 to 0.127mm (0.25 to 5mil) |

| Specific Gravity | 2.15 |

| Area Yield m²/kg/mm (ft²/lb/mil) | 726.5(90) |

| Flammability | UL-94 V-0 |

| Thermo-bondable | Yes |

| Adhesive Bondable | Yes |

| Tensile Strength MPa(psi) | 29.6(4,300) |

| Elastic Modulus MPa(psi) | 413(60,000) |

| Folding Endurance cycles | 4,000 |

| Coefficient of Friction | 0.2 |

| Elongation % | 400 |

| Dielectric Constant 60-10^8 Hz | 2.0 |

| Power Dissipation | < 0.0001 |

| Surface Resistance Ώ/cm² | 9 x 10^7 |

| Dielectric Strength volts/mm(volts/mil) | 165,354(4,200) |

| Surface Arc Resistance | Does not arc |

| Continuous use temperature ℃(℉) | 316(600) |

| Melt Point ℃(℉) | 327(620) |

Leave A Comment