ETFE Film

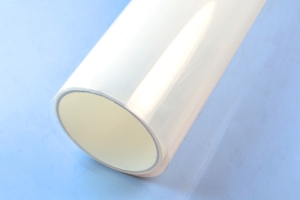

ETFE Film/ETFE Foil

ESONE’s ETFE film and foil is made from a co-polymer resin of ethylene and tetrafluoroethylene, utilizing a melt extrusion casting process. These ETFE films exhibit low permeability to liquids, gases, moisture, and organic vapors, while also offering high elongation and tear resistance. ETFE foils can be heat-sealed, thermoformed, and laminated to various materials. Importantly, ESONE ETFE films do not contain plasticizers, processing aids, or additives.

Advantages

- ETFE films are available in thicknesses ranging from 0.012 to 0.25mm (0.0005 inches to 0.010 inches) with a max width of 63” (1,600 mm). Custom slit widths are also available. The surfaces can be bondable through plasma treatment or chemical etching.

- These films have a broad continuous use temperature range from -200°C to 165°C(-328°F to 330°F) and can withstand short-term exposure up to 204°C (400°F), with a melt temperature minimum of 260°C (500°F).

- ETFE exhibits excellent non-stick properties, high elongation, and tear resistance. It offers over 90% light transmission and is effective in transmitting ultraviolet light while blocking far infrared wavelengths. The material demonstrates superior weatherability for outdoor applications.

- With a high dielectric strength of 215 kV/mm for 25 μm film (5,500 V/mil ), ETFE is free from plasticizers, processing aids, or additives, and it has low permeability to liquids, gases, moisture, and organic vapors.

ESONE ETFE films are available in four grades

- Made from 100% virgin premium grade ETFE resin.

- ETFE GP is the preferred choice for projects needing visual excellence.

- With its exceptional light transmission, clarity, and durability, ETFE is ideal for various applications, including architectural roofing, solar panel front glazing, decorative elements, anti-graffiti surfaces, and greenhouses.

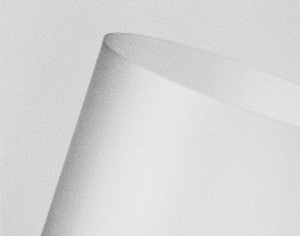

- Made from 100% virgin premium grade ETFE resin.

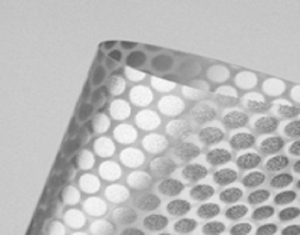

- ETFE AG is the preferred choice for projects that demand visual excellence.

- The unique attributes of ETFE, including high light transmission, clarity, and durability, make it essential for applications like architectural roofing.

- Offered in clear, white, or printed films for solar control and shading, with various standard patterns available, including:

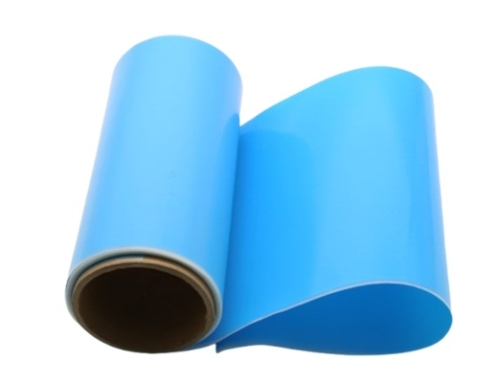

- ETFE MR is the preferred material for release films in high-temperature composite molding, thanks to its excellent non-stick properties and elevated upper use temperature in static applications.

- It provides a 20% higher area yield compared to FEP and PTFE, achieving 22.6 m²/kg for a 25 µm film ( 110 ft²/lb for a 1 mil film).

- The material features high elongation and outstanding conformability for complex, contoured molds.

- Standard colors include red and light blue, with custom color options available upon request.

- It is offered in various perforated patterns, including:

Specification

ESONE ETFE film provide excellent light transmission (over 90%) and clarity, allowing high transmittance of ultraviolet light and other wavelengths, excluding far infrared. They also have outstanding non-stick properties and superior resistance to outdoor weathering. ESONE’s ETFE foils are well-suited for applications in architecture, photovoltaic solar technology, and mold release.

We offer ETFE films and foils in thicknesses from 0.012 to 0.25mm (0.0005 inches to 0.010 inches), with a max width of 1,600 mm (63 inches), and slit widths can be requested. These films feature a high dielectric strength of 215 kV/mm for 0.025mm (equivalent to 5,500 V/mil for 1mil film). ETFE foils are reliable across a broad temperature range, with continuous use temperatures spanning from -200°C to 165°C ( -328°F to 330°F). They can withstand short-term exposure to temperatures up to 204°C (400°F), with a melt temperature starting at 260°C (500°F). Bondable surfaces, either plasma treated or chemically etched, are also available.

Color: Clear, Red, Blue and others

Width: Max 1,600mm (63 inches) Any slit width is available

Surface: Non-treatment, plasma treated or chemically etched

Temperature: Continuously working in temperatures ranging from -200°C to 165°C ( -328°F to 330°F)

| ETFE GP – General Purpose | ETFE AG –Architectural Grade | ETFE MG –Matte Grade | ETFE MR – Mold Release | ||

|---|---|---|---|---|---|

| General Properties | Test Method | ||||

| Specific Gravity | ASTM D792 | 1.74 | |||

| Area Yield m²/kg/um (ft²/lb/mil) | 0.89(110) | ||||

| Flammability | UL-94 | V-0 | |||

| Water Absoption % | <0.01 | ||||

| Standard width mm(in) | Max 1,600mm (63 inches) Any slit width is available | ||||

| Thickness Available mm(mil) | 0.012 to 0.25mm (0.5 to 10 mil) | ||||

| Colors | Clear | Clear | Clear | Red, Blue | |

| Mechanical Properties | |||||

| Tensile Strength MPa(psi) | ASTM D882 | 48(7,000) | 52(7,500) | 48(7,000) | 48(7,000) |

| Elongation at Break % | ASTM D882 | 300 | 350 | 300 | 300 |

| Tensile Modulus MPa(psi) | ASTM D882 | 965(140,000) | 850(125,000) | 965(140,000) | 965(140,000) |

| Initial Tear Strength g/mm(g/mil) | ASTM D1004 | 9,831(250) | |||

| Propagation Tear Strength g/mm(g/mil) | ASTM D1922 | 1,476(37.5) | |||

| Folding Endurance (MIT) cycles | ASTM D2176 | >50,000 | >80,000 | >50,000 | >50,000 |

| Thermal Properties | |||||

| Continuous Use Temp ℃(℉) | UL-746B | 165(330) | |||

| Melt Point ℃(℉) | ASTM D3418 | 260(500) | |||

| Electrical Properties | |||||

| Dielectric Strength volts/mm(volts/mil) | ASTM D149 | 216,535(5,500) | N/A | ||

| Dielectric Contant 1kHz | ASTM D150 | 2.6 | N/A | ||

| Dissipation Factor 1kHz | ASTM D150 | <0.0008 | N/A | ||

| Optical Properties | |||||

| Refractive Index | ASTM D542 | 1.4 | N/A | ||

| Solar Transmission % | ASTM E424 | 94 | N/A | ||

| Surface Treatments Available | |||||

| Chemical Etching | Available | ||||

| Plasma Treatment | Available | ||||

| Applications | |||||

| Composite Molding Process: Release Films | √ | ||||

| Chemical Process/Equipment | √ | ||||

| Heat Sealing/Welding/Melt Adhesive | √ | ||||

| Electrical/Electronics | √ | √ | |||

| Medical | √ | √ | |||

| Optical/Photovoltaics | √ | √ | |||

| Protective/Decorative | √ | √ | |||

| Architectural | √ | � | |||

Related Document

ESONE ETFE film is made from a co-polymer resin of ethylene and tetrafluoroethylene, are available in four grades

Which are ETFE GP – General Purpose, ETFE AG –Architectural Grade, ETFE MG –Matte Grade and ETFE MR – Mold Release

PDF| 646kb

Leave A Comment