PTFE Glass for Photovoltaic cells production and module lamination

PTFE Glass, full name is PTFE(Teflon) coated fiberglass fabric, is widely used as non stick release sheet in PV module vacuum lamination process, or used as conveyor belts for half cell welding machines. Since PV industry has very high request for the smooth surface, lifetime, mechanical and release property of PTFE coated fabric, so the performance of Teflon coating fabric will be a critical factor for maximum the production uptime, and increasing the quality of the module.

Using way of PTFE Glass for half cell welding and module lamination

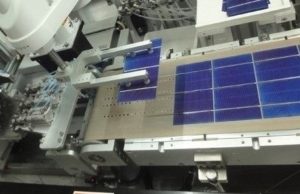

For half cell welding machines, PTFE endless belt or two layers laminated belt will be used as release belt to convey cell, in order to resist the high working temperature, offer great release property and maximum the production uptime.

This belt is also punched into two, four, six, eight or more holes per line, so that the solar cell can be caught up by the suction holes under the belt.

For module lamination machines, PTFE fabric is used as PTFE release sheet, or PTFE transport sheet.

Due to the high temperature and high pressure of the machine, reliable release property, long lifetime and high mechanical strength is the most important property for PTFE fabric.

And if there is any dent or defect on the surface of Teflon coating fabric, then the appearance of the module will be affected.

Property of PTFE fiberglass coated fabric

★ Heat resistant

PTFE fiberglass can resist heat and continuous work below 260 degrees.

★ Easy release surface

Coated with high quality Teflon, PTFE Glass has excellent release(non stick) surface.

★ High mechanical strength

In order for resist the continuous pressing, PTFE fabric is requested to has high mechanical strength and dimensional stability.

★ Abrasion resistant

Due to the heavy working for release & transportation, the surface of PTFE must be long lasting and abrasion resistant.

★ Long lifetime

High quality PTFE Glass will minimum the downtime of lamination machines, and will reduce the cost of production at the same time.

★ No defect on the surface

The defect on the surface will absolutely affect the appearance of module, and ESONE’s product has excellent smooth surface(no defect), which is a very reliable release sheet in the market.

Specification of PTFE fiberglass

| Product | Product Category | Coating |

|---|---|---|

| PTFE GLASS FABRIC | PREMIUM SERIES | PTFE |

| Properties | Metric | Imperial |

|---|---|---|

| Standard width Please ask for other widths | 1000, 1250, 1500, 2000, 2600 mm | 39.5, 49.3, 59.1, 78.8, 102.4 inches |

| Thickness | 0.25 mm | 0.0098 inches |

| Coated weight | 530 g/m² | 15.63 oz/yd² |

| PTFE content | 62 % | 62 % |

| Tensile strength | 460 N/cm Warp | 263 lbs/inches Warp |

| 400 N/cm Warp | 229 lbs/inches Fill | |

| Temperature resistance | -73 to +260 °C | -100 to +500 °F |

Click here to access Teflon Cloth YS9025AJ

Download related product for solar cell welding & module lamination, YS9025AJ-ESONE, YS9023AJ-ESONE, YS9030AJ-ESONE, YS9035AJ-ESONE

Or Anti static PTFE release sheet YS9025BJ-ESONE

Leave A Comment