Porous PTFE Fabrics, porous release sheet for curing process

Porous PTFE Fabrics has a high porosity than most PTFE coated fabrics, and this line combines fiberglass with lower levels of PTFE coating.

This material is used in applications which need airflow throw the fabric under pressure (air circulation for drying and curing processes), normal applications including casting sheets for uncured elastomers, vacuum bag bleeder cloth for composite molding in the manufacturing of composite aircraft components.

Unlike PTFE premium series, it is more flexible, much stronger and can be wrapped around curved shapes.

Porous PTFE Fabrics

After many years development, Youngsun offering Porous series with balanced PTFE content and porosity.

With high porosity surface, this Porous PTFE Fabrics allow air pass the fabric during the production such as vacuum bag bleeder cloth, which allow products to cure and out gas through fabric.

In the meantime, PTFE content will still ensure easy release and high tensile strength. Youngsun will balance these two properties.

Applications of Porous PTFE coated fabrics

Because of their unique properties, these fabrics are excellent for using in a wide range of applications, from the manufacture of polymers to a release medium for composite molding process.

Applications of Porous PTFE Fabrics:

★ Aerospace, Communications & Milltary, Composite mold release in vacuum bag, or use as release sheets for fabricating glass-resin structures.

★ Polymer Processing: Manufacture of silicone rubber sheets, Curing rubber and plastic foams and sponge.

★ Insulation and protection.

★ Seperation materials.

★ Drying painted or lacquered products.

★ Release sheet for heat sealing machines

Specifications of porosity PTFE fabric

| Product | Product Category | Coating |

|---|---|---|

| PTFE GLASS FABRIC | POROUS SERIES | PTFE |

| PTFE Fabric Porous Serie | |||||

|---|---|---|---|---|---|

| Style | Standard Width(mm) Please ask for other widths | Normal Thickness (mm) | Weight (g/m2) | PTFE Content (%) | Tensile Strength Warp/Fill (N/cm) |

| YS9003P-ESONE | 1000, 1250, 1500 | 0.025 | 40 | 50 | 60/52 |

| YS9006P-ESONE | 1000, 1250, 1500 | 0.06 | 66 | 28 | 160/146 |

| YS9010P-ESONE | 1000, 1250, 1500 | 0.10 | 140 | 24 | 240/200 |

| YS9020P-1 -ESONE | 1000, 1250, 1500 | 0.20 | 260 | 23 | 500/480 |

| YS9020P-2 -ESONE | 1000, 1250, 1500 | 0.20 | 350 | 43 | 460/430 |

| YS9020P-3 -ESONE | 1000, 1500, 2600 | 0.20 | 320 | 37.5 | 460/430 |

| YS9023P-ESONE | 1000, 1500, 2600 | 0.23 | 278 | 26 | 460/430 |

| YS9025P-ESONE | 1000, 1500, 2600 | 0.25 | 370 | 32 | 520/492 |

| YS9040P-ESONE | 1000, 1250, 1500 | 0.40 | 650 | 35 | 750/580 |

Porous PTFE Fabrics

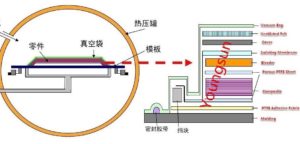

How to use Porous PTFE Fabric for Vacuum bag systems

Porous PTFE Sheet is used to touch the composited material directly, the enough porosity ensure the redundant resin and air can pass though PTFE sheet, and this bag can be vacuumized thoroughly.

This fabric will also providing a shiny surface for composited material after release.

Vacuum bag system will also use PTFE adhesive fabric to stick to molding, which is on the bottom of the vacuum bag.

Kaixo, zure prezioa jakin nahi nuen.