Aerospace

ESONE PTFE coated fabric with or without adhesive are used in the manufacturing of aircraft composited components, such as helicopter rotor blades, satcom and weather radomes, structural component like tail sections, wings and wire harness protective insulation.

In the full range of applications, the release properties, mechanical properties and porosity of the product selected are critical to the performance of the manufacturing process and the quality of the products produced.

Product

Vacuum Bagging Bleeder Cloths

Vacuum Bagging Bleeder Cloths, make of PTFE coated fiberglass fabric with low level of PTFE content, which has a higher porosity than normal PTFE coated fabric. In this case, air and extra resin will be allowed for passing through the bleeder cloths. This fabric is used as release sheet and bleeder cloth, for the manufacturing of aircraft composites, including satcom and weather radomes, helicopter rotor blade, structural components like wings, tail section, fuselage component and so on.

Technical data sheet of Bleeder Cloth, YS9006P-ESONE

Related product like Non porous release sheet YS9007AJ-ESONE, YS9008AJ-ESONE

- Clean release property

- Controlled porosity

- High mechanical strength

PTFE Mold Release Tape

PTFE Mold Release Tape, make of woven fiberglass coated with high quality PTFE(TEFLON), and back side coated with Silicone PSA. This mold release tape has higher tensile strength than normal self adhesive PTFE fabric. In this case, ESONE adhesive tape will be easily took down after repeatedly used.

ESONE mold release adhesive fabric is used to stick the molding, for the manufacturing of aircraft composites, wind power blade composite, like satcom and weather radomes, helicopter rotor blade, structural components like wings, tail section, fuselage component and so on.

Technical data sheet of PTFE Mold Release Tape, YS7007AT-ESONE, YS7013AT-ESONE

The request for PTFE mold release tape is as follows.

- Outstanding easy release property

- Low adhesion, easy to peel

- Excellent mechanical strength, can be reusable

- No adhesive left after peeled.

Applications

Aircraft composites manufacturing

PTFE coated fiberglass fabric is widely used in various aircraft composite manufacturing process, including vacuum bagging technique, open molded and hand lay-up process.

PTFE bleeder cloth and PTFE mold release tape will be used directly to the mold and product, allowing for a easy and clean release after the curing process of aircraft composite. ESONE porous PTFE fabric can ensure perfect release while maintaining the breathable property, which can allow air and volatiles to escape during production. And due to the high mechanical strength of mold release tape, ESONE adhesive fabric is reusable and provide clean release.

The applications including helicopter rotor blades, satcom, weather radomes and others

Wind Turbine Blades Release

This application also use PTFE porous fabric and PTFE adhesive fabric. We customize PTFE porous fabric with balanced porosity & release property, and has high mechanical strength. For PTFE adhesive fabric, our mold release tape is easy release and has high mechanical strength, so that it can be reused many times easily.

ESONE PTFE fabric also names as heat resistant peel ply, this allows for the composite to be peeled from fabric after it is cured, and the result is a perfectly smooth surface.

PTFE Radome Cover

Due to the low dielectric constant, low loss tangent and low interference with microwave frequencies, ESONE high performance PTFE coated fiberglass fabric is the perfect solution for radome cover for devices such as satellite terminal, portable radomes for VSAT, flexible planar radomes, Fly Away satellite communications terminals, and microwave communication antennas.

Meanwhile, ESONE PTFE coated fabric has strong mechanical strength, which is easy to install and can prevent bird’s peck.

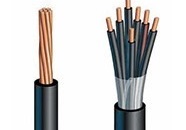

Convoluted Tubes & Wire wrap insulation

Due to the high dielectric strength of PTFE and strong mechanical strength of glass fiber, PTFE coated fabric is the great solution for shielding of electrical cables and individual components.

What’s more, since PTFE tape or fabric offer abrasion resistant insulation and low friction surface, ESONE’s product can serve the most demanding industrial electrical needs in modern aircraft industry.

Get Social